Description

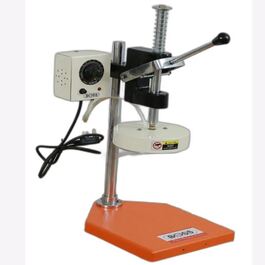

A neck sealer is a tool used to apply heat to the necks of bottles or other containers with a tamper-evident seal, such as a plastic sleeve or cap. The heat melts the seal and creates a secure and tamper-evident closure. Neck sealers are commonly used in the packaging and bottling industry for a variety of applications, including:

Food and beverage packaging: Neck sealers are used to seal bottles of juices, soft drinks, sauces, and other food and beverage products to ensure freshness and prevent tampering.

Pharmaceutical packaging: Neck sealers are used to seal bottles and vials of medicines, vitamins, and other pharmaceutical products to ensure that they are safe and free from contamination.

Chemical packaging: Neck sealers are used to seal bottles and containers of chemicals, such as cleaning agents and industrial solvents, to prevent spills and ensure safe handling.

Cosmetics packaging: Neck sealers are used to seal bottles and containers of cosmetics, such as lotions, creams, and shampoos, to prevent contamination and ensure product quality.

Overall, neck sealers provide a reliable and efficient method for creating a tamper-evident seal on bottles and containers. They are commonly used in industries where product safety and quality are of utmost importance, and can help to prevent product tampering, contamination, and spills.